Toyota 3SGTE – The Ultimate Guide

Known for powering the likes of the Celica GT-Four, the 3SGTE has earned itself a popular following. Here’s what makes this turbocharged inline-four great.

Jump To Section

Introduction

Toyota has long been known as one of the best automotive manufacturers in the JDM and global markets.

One of the primary reasons for their tremendous success is the engines they produce, combining impressive power with incredible reliability.

The ‘golden era’ of Toyota engines was probably during the ’90s when some of their engines were deemed ‘legendary’ by consumers and critics alike. An example would be the 3.0L (2997 cc) twin-turbo 2JZ-GTE from the Supra MKIV.

Similarly, around this time, Toyota built the 3SGTE, which continued to be produced for 21 years (1986-2007).

The engine was improved drastically during this time, and there exist five generations of the 3SGTE, all of which are the topic of today’s article.

We will overview the significant changes in each generation of the engine, the applications of the engine, and its tuning potential, reliability, and common faults.

3SGTE Applications

- 1986-1989 Toyota Celica GT-Four ST165 (first-gen engine)

- 1990-1993 Toyota Celica GT-Four ST185 (second-gen engine)

- 1990-1993 Toyota MR2 (second-gen engine)

- 1994-1999 Toyota Celica GT-Four ST205 (third-gen engine)

- 1994-1999 Toyota MR2 (third-gen engine)

- 1997-2001 Toyota Caldina ST215 (fourth-gen engine)

- 2002-2007 Toyota Caldina ST246 (fifth-gen engine)

3SGTE Engine Specs

The 3SGTE is a turbocharged 2.0L (1998 cc), in-line four-cylinder gasoline engine which produces 182 horsepower at 6000 rpm and 250 Nm of torque at 4000 rpm in its first generation.

By the fifth generation, the GTE produced 256 horsepower at 6200 rpm and 324 Nm of torque at 4400 rpm.

The 3S-GTE is based on the 3S-GE engine. This engine has been used in many projects because of its tuning potential, tough build, and decent specs.

Usually, we see a manual transmission coupled with the 3S-GTE, although the Caldina GT-Four came with a Tiptronic transmission.

Although it is based on the naturally aspirated 3S-GE, the 3S-GTE has added under-piston oil squirters and a lower compression ratio to accommodate the addition of the turbocharger.

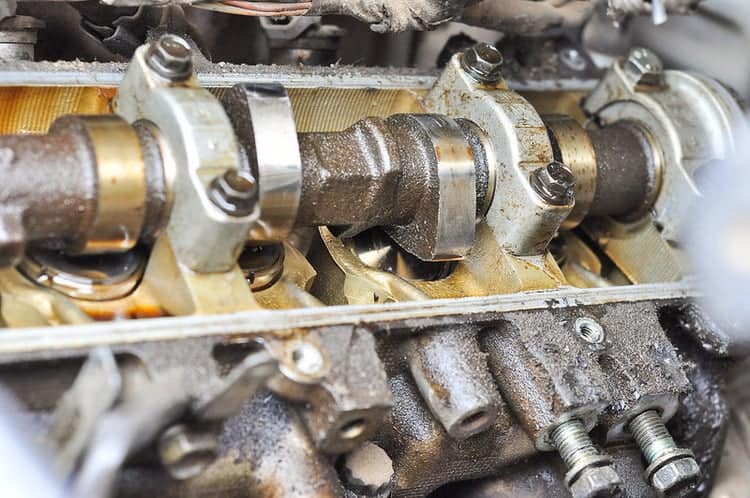

This is one of the few engines on which Toyota had worked in conjunction with Yamaha. Yamaha had designed the 16-valve dual overhead cam (DOHC) cylinder head used in this engine.

The cylinder head is made using aluminum alloy, with a firing order of 1-3-4-2 using a distributor-based system.

A single-timing belt drives the exhaust, intake camshaft, water, and oil pumps.

A shim-over bucket system is employed to adjust the valve clearance in the first and second generations of the engine. A shim under bucket system is fitted in later generations of the engine.

The engine pistons are designed to endure high-temperature levels, so the aluminum alloy is used again. The pistons have an indentation incorporated to prevent them from hitting the valves in the case of breakage of the timing belt.

Engine Specs

| Configuration | Inline-four |

| Displacement | 2.0L (1998cc) |

| Horsepower | 182-256 HP |

| Torque (Nm) | 250-324 Nm |

| Aspiration | Turbocharged |

| Block Material | Cast Iron |

| Head Material | Aluminum alloy |

| Valvetrain | DOHC, 16 valves |

| Bore x Stroke | 86mm x 86mm |

| Compression Ratio | 8.5:1 to 9.0:1 |

The naturally aspirated and the turbo version of the 3S was on the market for a long time, and during that time, they evolved significantly.

The NA and the turbo 3SGTE can be split into five generations, and the difference between the power output from the first generation to the last shows you the evolution’s extent.

The 3S-GE initially started with a pretty modest 135 horsepower and ended with a respectable 210 horsepower.

However, the 3S-GTE, on the other hand, started with 185 horsepower and ended with 260.

3S engines have the same bore and stroke throughout generations and feature a square engine design with both bore and stroke at 86 millimeters. This tells us that the 3s aimed for an optimal balance between valve size, performance, power, and torque.

The naturally aspirated 3S-GE employed many different variable valve timing technologies. It started with the primitive TVIS, which is the same one that you can find on the early versions of the 4A-GE engine.

Like for the 4A-GE, Toyota got rid of TVIS pretty fast for the 3S, in favor of the ACIS, which stands for acoustic control induction system. (ACIS had proved to be significantly more efficient than TVIS)

The 4th generation of the 3S-GE came with proper modern variable valve timing technology, which in the case of Toyota is known as VVTi. Generation 5 of the 3S has dual VVTi.

However, unlike on the 2ZZ-GE engine, this doesn’t have a variable lift and simply affects valve timing. Nevertheless, it’s a handy feature for increasing the performance of your engine.

The fourth and fifth generations of the 3S-GE are known as BEAMS engines.

BEAMS stands for Breakthrough Engine with Advanced Mechanism System and should tell you everything that was going on in these engines.

Unfortunately, the BEAMS was only available in the Japanese markets.

Regarding the specs, the BEAMS 3S was significantly superior to the first, second, and third generations as it had bigger intake valves, better variable valve timing, and more compression.

Compression was increased to an impressive 11.5 on the last generation of the BEAMS. This last generation is known as the BEAMS black top.

The black top is pretty exotic because it has titanium valves which reside at 35 millimeters for the intake – an impressive intake valve size for this engine displacement.

The included valve angle is also a bit narrower in the fourth and fifth generations of the 3S, which is another thing that helps better performance. For the 3S-GTE particularly, variable valve mechanisms were simply dropped.

You have a nice turbo, and you get boost, so Toyota thought, “who cares about variable valve timing?”

The ignition system was also improved in generations four and five, moving from a distributor-based system to a much more accurate coil-on-plug system.

Regarding the compression, we can see the compression increased from generation one to two of the 3S-GTE but dropped for the 3rd generation. This is accompanied by an increase in boost, on the other hand.

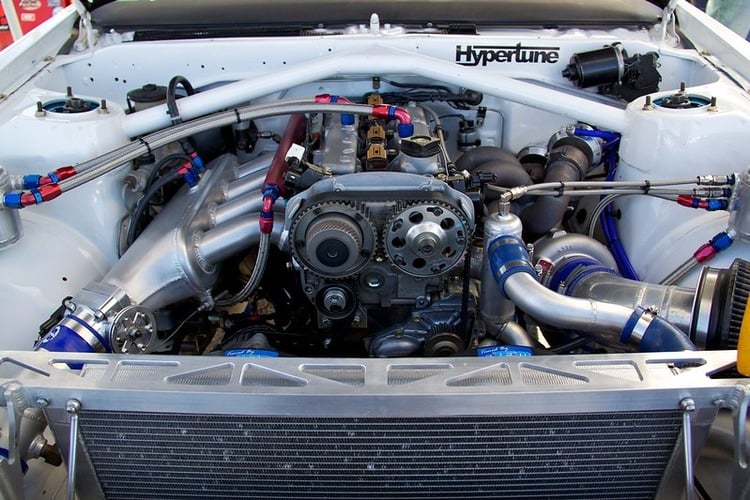

All 3SGTE engines are single turbo setups, and the turbo changes for each generation. This is probably why there is an increase in power.

It’s also worth noting that the fourth and fifth gen Japan-only 3SGTE engines have something you do not see every day: the exhaust turbine housing of the turbo is cast together with the exhaust manifold, which means that the stock manifold and turbo are inseparable.

The intercooler also changed from generation to generation and went from a water-to-air type to an air-to-air type. The water-to-air type is an apparent preference to air-to-air.

Factory boost also increased from generation to generation, and it peaked at 13 psi for generations three, four, and five. The boost fuel cut also increased and peaked at 21 psi.

3SGTE Tuning Potential

To increase the power output of this engine, some possible options include:

- Installing a larger turbocharger: This will increase the air entering the engine, resulting in more power.

- Upgrading the intercooler: The intercooler is responsible for reducing the temperature of the compressed air entering the engine. An upgraded intercooler will be more efficient at reducing the temperature of the air, which will result in more power.

- Installing a high-performance exhaust system: This will reduce backpressure in the exhaust system, allowing the engine to breathe more efficiently, resulting in more power.

- Installing a high-performance intake system will increase the air entering the engine, resulting in more power.

- Upgrading the fuel injectors: larger fuel injectors will allow the engine to receive more fuel, resulting in more power.

- Upgrading the ignition system will ensure that the engine receives the maximum spark, which will result in more power.

- Upgrading the engine management system will allow you to fine-tune the engine for maximum power output.

Note: It’s important to note that these modifications will require professional installation and tuning and may also require other supporting modifications. Additionally, it’s also important to note that these modifications will void the warranty of your engine and may cause unexpected damage if not done correctly.

Many old articles criticize the ignition system of the 3S-GTE, and they usually talk about cap/rotor wear, etc. Over 700 WHP can be made using the stock ignition system. With the right upgrades and correct tuning, the 3S-GTE can be translated into a supercar killer.

Note#2: WHP figures below are for a second-gen 3S-GTE installed in an SW20 MR2.

For a Stage 1 upgrade, we recommend letting the engine breathe a bit better. This can best be achieved by upgrading the exhaust system. By increasing the diameter of the exhaust pipes or installing a test pipe, you can expect better overall airflow and some power gain.

This would result in a much louder and meaner-sounding car. Moreover, the boost can be increased to around 15-16 psi with an aftermarket boost controller, either manual or electronic. That is the beauty of installing a better flowing exhaust – your turbo also performs better!

The aim should be to bypass the factory boost control setting programmed in the ECU. Also, make sure to install an aftermarket boost gauge. Fuel gets cut at a certain point when the turbo is spinning, and to avoid this, you would also need a fuel-cut defender.

The overboost fuel cut limit from the factory is set to low psi levels, so this step is essential. You can expect anywhere between 200-230 WHP from a Stage 1 upgrade.

Going one step further towards the Stage 2 tuned 3S-GTE, we would find that it is necessary to upgrade the turbocharger. The factory stock CT20b is a great turbo, and with some minor upgrades, for example, a 46-trim compressor wheel or 10-degree exhaust wheel clip, the power rating can be increased.

Alongside this, an upgraded air intake (free-flowing) and an upgraded intercooler would work well.

A wide-band O2 sensor is a type of sensor that is installed in the exhaust system of an engine and measures the amount of oxygen in the exhaust gas. This information is then used to calculate the engine’s AFR.

When tuning a Toyota 3S-GTE engine, a wide-band O2 sensor can monitor AFR in real-time and adjust the engine management system accordingly to ensure that the engine is running at the optimal AFR.

This can help increase power output by ensuring that the engine receives the correct amount of fuel for the amount of air it is receiving.

Additionally, installing a wide-band O2 sensor can help identify and diagnose any issues with the engine’s fuel system, such as a malfunctioning fuel injector or a clogged air filter.

It is advised not to run leaner than 12.0:1. A Stage 2 tuned vehicle would produce nearly 250-280 WHP.

Finally, a Stage 3 tuned 3S-GTE would have many upgraded components, and the true potential of the 3S-GTE would start to unleash.

A Stage 3 tune would include all the previous upgrades and is the stage where the factory fuel system and ECU will be upgraded.

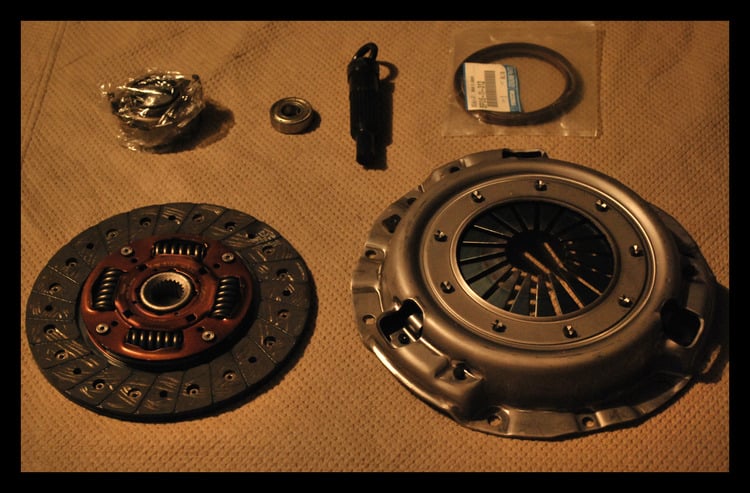

This is also the stage where upgrading the clutch and flywheel is recommended.

One option for a clutch upgrade is to install a high-performance, single-mass flywheel, and clutch kit. This will reduce the rotational mass of the flywheel, allowing the engine to rev more quickly and provide more power.

A high-performance clutch kit will also have a higher clamp load and more durable construction.

Another option is to install a twin-disc clutch. A twin-disc clutch consists of two friction discs, which increases the clutch’s capacity to transmit power from the engine to the transmission. This can handle more power and torque than a single-disc clutch, but it also tends to be more expensive.

A third option is to install a ceramic clutch made from ceramic materials rather than metal.

These are known for their high heat resistance, durability, and ability to handle high power and torque loads.

It’s important to note that a clutch upgrade will also require the installation of a high-performance pressure plate, which will help to transmit the increased power from the engine to the transmission.

The power rating can go much higher than this, but that would require the engine to be rebuilt with new forged components to withstand tougher conditions.

Out of a fully forged engine, you can expect anywhere between 750-800 WHP.

In terms of engine internals, some options include:

- Installing high-performance connecting rods

- Installing high-performance pistons

- Installing a high-performance crankshaft

- Installing a high-performance cylinder head

3SGTE Reliability & Common Issues

A 20+-year-old turbocharged engine will be as reliable as your wallet allows.

Don’t be surprised if stuff like belts, seals, or hoses break because the engine wasn’t appropriately maintained in the past.

You would want to go towards quality parts only to ensure that your engine performs at its best and for a long time.

The Toyota 3S engine is reliable and excellent for potential project builds.

If you’re willing to invest the time, and effort and, most importantly, put some money into a 3S-GTE, you will probably end up with a killer, high-performing machine.

(10 votes, average: 3.50 out of 5)

(10 votes, average: 3.50 out of 5)